An in-depth analysis of the reasons behind the collapse of European battery companies like Northvolt and Britishvolt, focusing on financial challenges, lack of innovation, and the competitive edge of Chinese and Korean battery manufacturers. This article also explores the long-term implications for Europe's battery market and its reliance on Chinese batteries.

In November 2024, Northvolt, hailed as the leader of the European battery industry, filed for bankruptcy protection in a bid to raise up to $245 million to save itself. While not officially bankrupt, the company’s dire financial situation, faltering mass production progress, and canceled major orders all point to Northvolt’s failure.

Financial Woes and the Fall of Northvolt

Recent discussions about Northvolt’s collapse focus primarily on its poor financial performance. According to Crunchbase data, the company completed 14 rounds of funding, raising a total of $13.8 billion, yet its accounts hold a mere $30 million, with liabilities soaring to $5.84 billion.

When Pan Jian, a board member of CATL, was asked about Northvolt’s reported outreach for investment, he remarked, “Investing in Northvolt is not our priority.” He acknowledged past discussions about potential collaboration through licensing but admitted, “We didn’t know they were in such severe financial distress.”

The Core Issue: Lack of Innovation

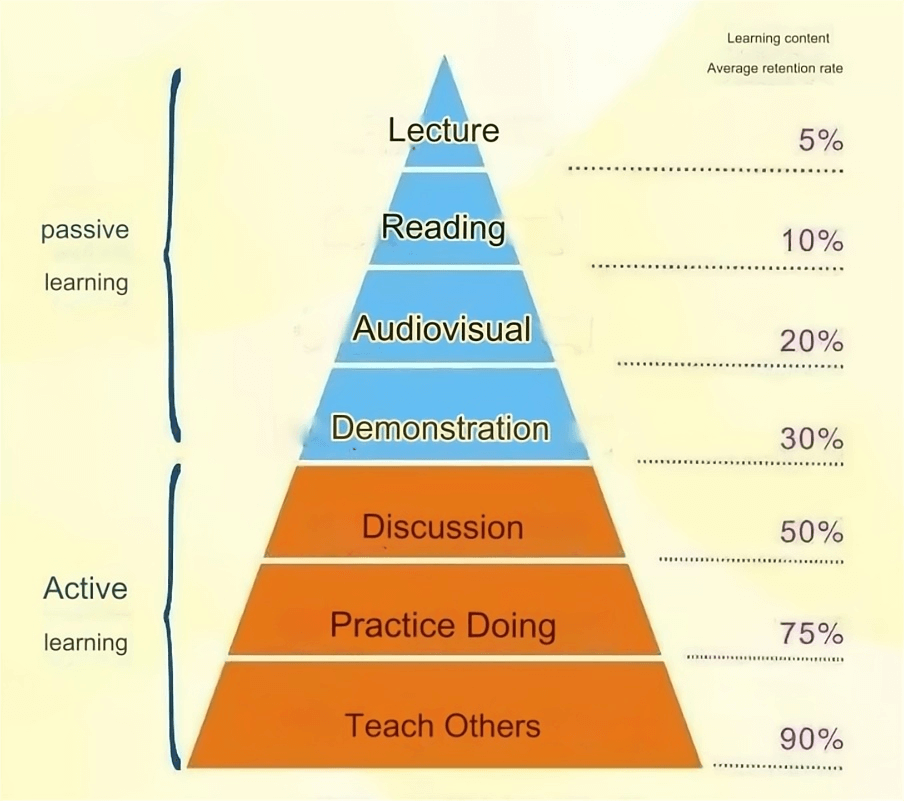

The fundamental reason behind Northvolt’s failure, and that of other European battery companies, is not just financial difficulties but a comprehensive lag in innovation.

1. European Battery Companies Were Too Slow

Northvolt is not an isolated case. In January 2023, Britishvolt, once a promising UK-based company, filed for liquidation. Founded in 2019, it announced £2.4 billion in funding across five rounds between September 2021 and November 2022, but less than £100 million was actually secured. Its proposed £2.6 billion gigafactory in Northumberland never progressed beyond concept drawings.

Similarly, AMTE Power, another UK company, faced bankruptcy in 2023 after exhausting its final £2.1 million funding in September. It filed for bankruptcy in January 2024.

France’s Verkor fares slightly better, having raised €3.8 billion, with €1.3 billion of debt financing secured in May 2024. While its Dunkirk plant is under construction, delays from 2023 to 2025 and reliance on debt pose risks if revenues fall short.

ACC (Automotive Cell Company), supported by Stellantis, managed to deliver its first batch of batteries in 2024 but faces skepticism due to suspending its Italian and German projects.

German company Varta and Norwegian firm FREYR, though operational, focus on consumer electronics and energy storage batteries respectively, with limited impact on the automotive market. Both have seen steep stock price declines—Varta by 98.55% and FREYR by 80.04%.

The common thread among these failures is an inability to scale up battery production effectively. CATL’s chairman once pointed out that European battery companies made mistakes in design, process, and equipment, preventing large-scale manufacturing and delivery.

2. The Impact of Chinese Innovation

Initially, European battery companies faced no significant barriers to manufacturing. However, Chinese battery companies disrupted the industry with groundbreaking innovations starting in 2021, exemplified by BYD’s blade battery.

Chinese companies quickly improved stacking technology, with equipment efficiency surging from 0.6–0.8 seconds per sheet in 2021 to 0.116 seconds per sheet in 2024, enabling mass production.

The shift to lithium iron phosphate (LFP) batteries, driven by Chinese advancements, relegated the once-dominant nickel-cobalt-aluminum (NCA) and nickel-manganese-cobalt (NMC) chemistries to second place.

European companies struggled to adapt. Their insistence on rigid standardization and slow execution in a fast-evolving market left them unable to compete.

The Three Major Impacts of These Failures

1. Prolonged Dependence on Chinese Batteries

The immediate consequence is Europe’s continued reliance on Chinese batteries for at least a decade, whether through imports or local production by Chinese companies.

By 2024, CATL surpassed LG Energy Solution as Europe’s top battery supplier, with a 34% market share in Q1 2024. Combined with other Chinese manufacturers, Chinese batteries now account for over 40% of Europe’s market.

This reliance extends to energy storage, where Chinese LFP batteries dominate. Safety concerns surrounding NMC batteries have accelerated this shift, with BYD holding a 30% market share in Europe’s storage market by mid-2024.

2. Korean Companies’ Gains in Market Share

While China leads, Korean companies like LG and Samsung SDI have also benefited from the collapse of European competitors. European automakers seeking supply chain security are redirecting orders to Korean manufacturers.

3. Recalibration of Industry Overcapacity Projections

The failure of European battery companies is forcing a reassessment of projected overcapacity in the battery industry. Of the 2 TWh of planned capacity in Europe as of October 2024, at least half is unlikely to materialize.

This recalibration particularly impacts the LFP sector, where China holds a monopoly. Overcapacity fears are being replaced by a focus on actual production and inventory levels.

Conclusion

The failures of European battery companies highlight structural weaknesses in their innovation, execution, and adaptability. Meanwhile, Chinese companies remain at the forefront, leveraging their comprehensive advantages in materials, engineering, manufacturing processes, and equipment.

For the next decade, Chinese batteries will be the cornerstone of Europe’s energy transition, with Korean companies as supplementary players. European efforts must focus on facilitating local production by Chinese firms to reduce dependence on imports.